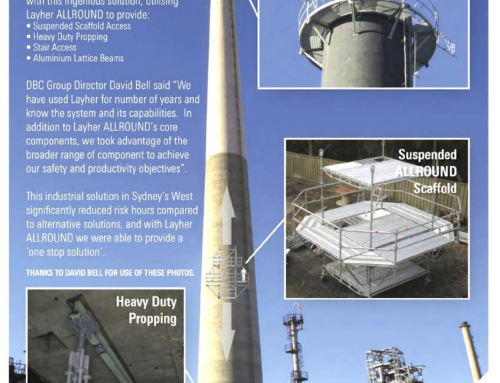

LOCATION

PORT KEMBLA STEELWORKS, NEW SOUTH WALES

CLIENT

BLUESCOPE STEEL

JOB DESCRIPTION

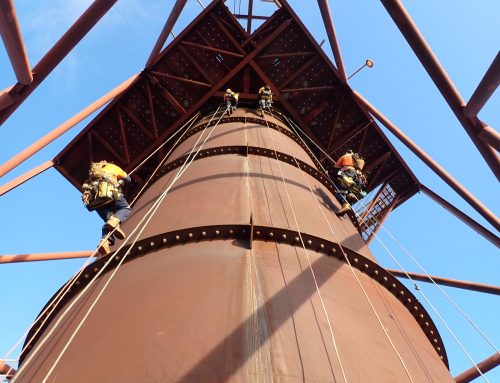

The project required gutter sections, each weighing 350kg, to be cut, replaced and welded in situ on the roof, 50m above live torpedo ladles and an executive walkway on the ground. Plus installation of 125 metres of horizontal and vertical external and internal downpipes which were cut and welded in situ. DBC’s qualified trade teams utilised an integrated rope access and engineered HUSIK roof access system. The methodology limited overall crane use, scaffold construction and site disruption within, around and on the BOS roof.